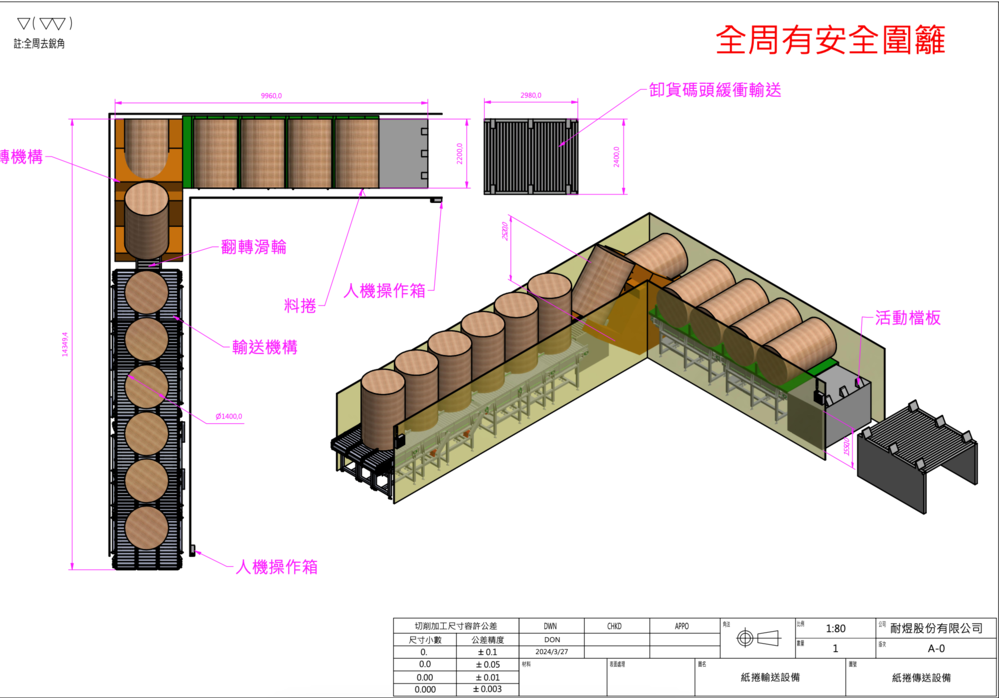

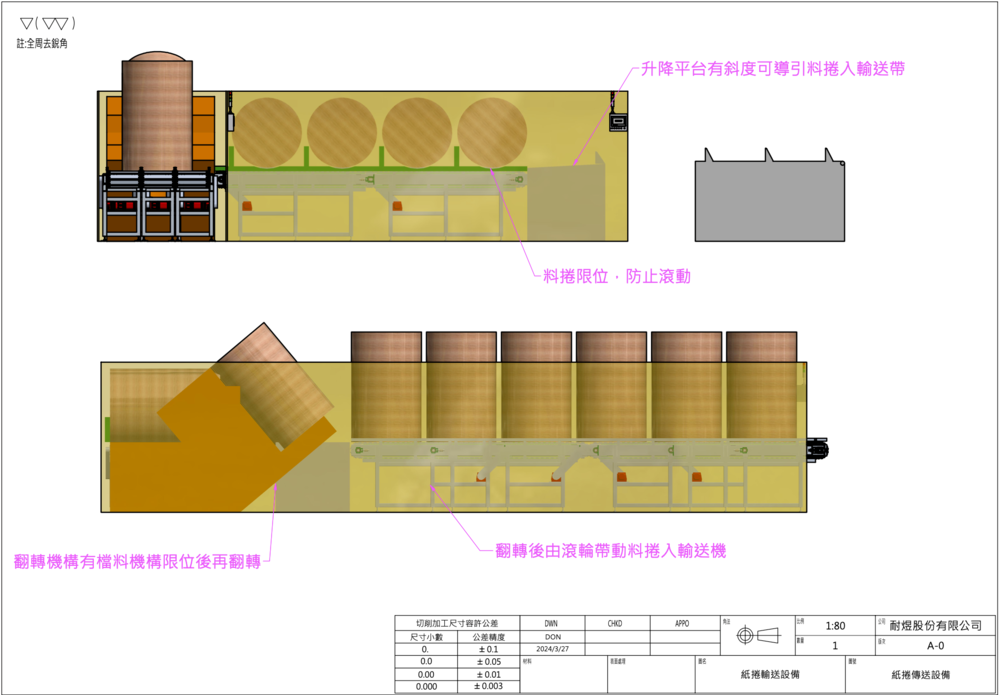

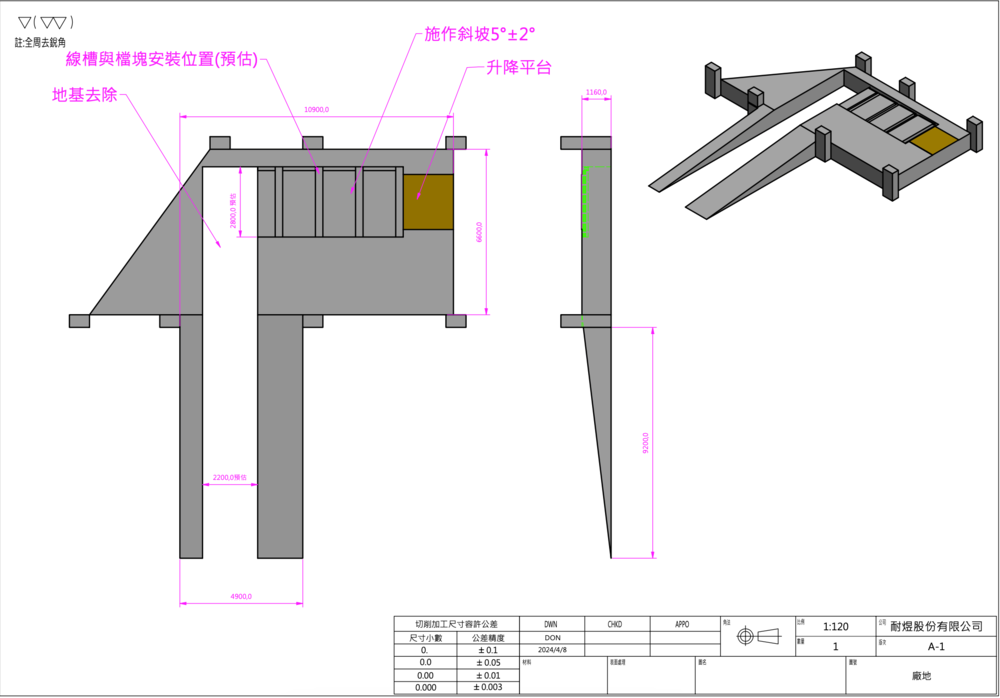

Handling System

Automation: Many handling systems incorporate automation technologies to reduce human intervention, increase speed, and enhance precision.

Flexibility: Modern handling systems are often designed to be adaptable to various product sizes, weights, and types, allowing for seamless integration into different operational environments.

Scalability: Handling systems can be scaled up or down depending on the size of the operation, from small conveyor belts in a single production line to large, complex networks of conveyors and AGVs in a major distribution center.

Integration: Advanced handling systems can be integrated with other systems, such as inventory management or production control systems, to provide real-time data and improve decision-making processes.

Safety: These systems are designed with safety features to protect workers from accidents and injuries, often incorporating sensors, alarms, and emergency stop mechanisms.