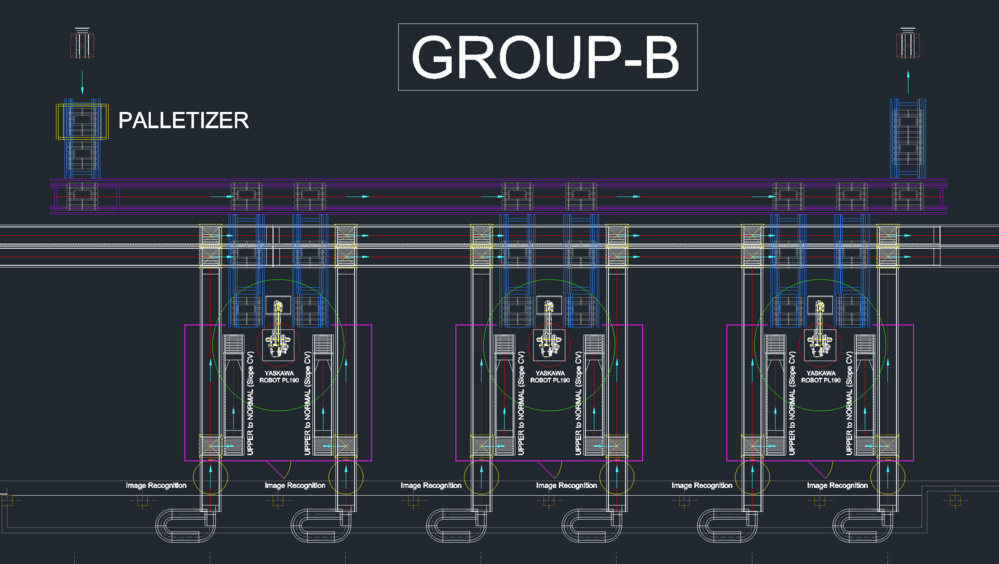

Conveyor & Robot Arm Palletizing

Conveyor System

The conveyor system consists of a series of belts or rollers that transport goods from one point to another within the facility. These belts are configured to move at controlled speeds and can be inclined or declined based on the specific requirements of the production line.

- Conveyor Belts: The conveyor system consists of a series of belts or rollers that transport goods from one point to another within the facility. These belts are configured to move at controlled speeds and can be inclined or declined based on the specific requirements of the production line.

- Sorting Mechanism: The conveyor system may include sorting mechanisms such as diverters, pushers, or sensors that help segregate products based on predetermined criteria. This ensures that items are correctly directed to the appropriate processing or packaging station.

- Pallet Conveyor: There may be a dedicated conveyor specifically designed for pallets, allowing for seamless movement of pallets through the palletizing process.

- Robot Arm

- Articulated Robot Arm: The robot arm is an articulated robotic manipulator equipped with joints, allowing it to mimic the movements of a human arm. It is programmed to pick up, move, and place items with precision.

- End-of-Arm Tooling (EOAT): The robot arm is equipped with specialized end-of-arm tooling designed for palletizing. Grippers, suction cups, or other custom tools may be attached to the robot arm to securely grasp and lift products.

- Vision System: Some advanced systems incorporate vision systems, including cameras and sensors, to enable the robot arm to identify and locate items on the conveyor. This enhances the system's flexibility to handle various product types.

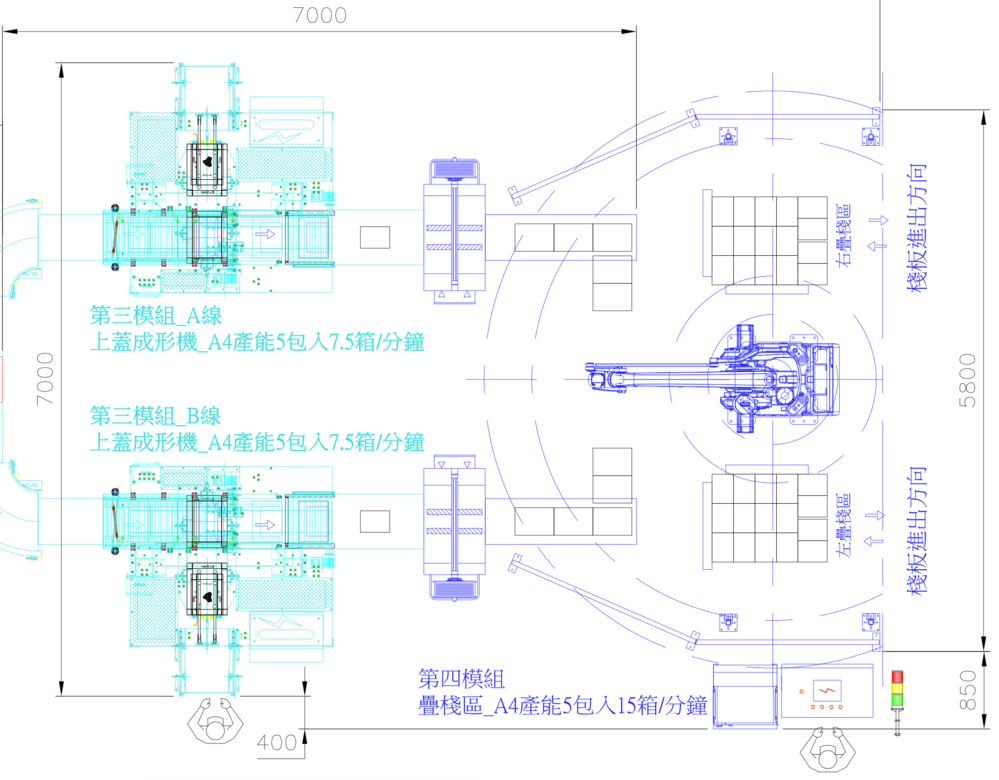

- Palletizing Station:

- Palletizing Area: The system includes a designated palletizing area where the robot arm places items onto pallets. This area is typically equipped with safety features to ensure the well-being of workers and efficient operation.

- Palletizing Patterns: The robot arm is programmed to follow specific palletizing patterns based on the type and size of products being handled. It optimizes stacking to maximize pallet stability and storage efficiency.

- Control System:

- PLC (Programmable Logic Controller): The entire system is controlled by a PLC or a similar control system. It coordinates the movements of the conveyor system, robot arm, and other components to ensure seamless integration and synchronization.

- Human Machine Interface (HMI): The HMI provides a user-friendly interface for operators to monitor and control the system. It allows for programming changes, troubleshooting, and real-time system status updates.

Automated Material Handling

- The conveyor system automates the movement of products from one point to another, reducing the need for manual labor in material transportation.

Robot Arm Precision

- The robot arm is equipped with precise and programmable movements, allowing it to handle various products with accuracy and repeatability.

End-of-Arm Tooling (EOAT) Options

- The robot arm's end-of-arm tooling is customizable to accommodate different product types and sizes. Grippers, suction cups, or other specialized tools can be selected based on the handling requirements.

Product Recognition and Sorting

- Vision systems and sensors enable the robot arm to recognize and sort products on the conveyor. This feature enhances flexibility by allowing the system to adapt to different shapes, sizes, and packaging variations.

Palletizing Patterns and Configurations

- The system can be programmed to follow specific palletizing patterns based on product dimensions and stacking requirements. This ensures optimal use of pallet space and stability during transportation and storage.

Variable Speed Control

- The conveyor system allows for variable speed control to accommodate different production rates, ensuring that products are conveyed and palletized at the desired pace.

Integration with Warehouse Management Systems (WMS)

- The system can be integrated with WMS or other control systems to enhance overall facility automation, allowing for seamless communication and coordination with other processes.

Safety Features

- Incorporation of safety features such as emergency stop buttons, safety barriers, and sensors to ensure the protection of workers and prevent accidents in the palletizing area.

User-Friendly Interface

- A human-machine interface (HMI) provides an intuitive control interface for operators. It allows for easy programming, monitoring, and adjustments to the system parameters.

Flexibility for Multiple Product Lines

- The system is designed to handle diverse product lines, making it adaptable to changes in production requirements and allowing for quick reprogramming for different products.

Reduced Labor Costs

- Automation of palletizing tasks decreases the reliance on manual labor, reducing labor costs and minimizing the risk of injuries associated with repetitive tasks.

Fault Detection and Diagnostics

- The system includes features for fault detection and diagnostics, aiding in quick identification and resolution of issues to minimize downtime.

Space Efficiency

- Optimal design for space efficiency, ensuring that the conveyor and palletizing components are configured to fit within the available workspace.

Energy Efficiency

- Energy-efficient components and programming to minimize power consumption and contribute to overall sustainability goals.

Remote Monitoring and Maintenance

- Some systems offer remote monitoring capabilities, allowing for real-time tracking of system performance and facilitating remote maintenance and troubleshooting.

Food & Beverage

Streamline the packaging of food and beverage products such as bottles, cans, boxes, and bags. The system ensures precise stacking and palletizing, maintaining product integrity while increasing throughput.

Manufacturing

Enhance the efficiency of manufacturing operations by automating the palletizing of finished goods, components, and materials. This system can handle diverse product types and sizes, improving overall production line performance.

Logistics & Distribution

Optimize warehouse operations by automating palletizing tasks for outgoing shipments. The Conveyor & Robot Arm Palletizing system accelerates order fulfillment, reduces errors, and maximizes space utilization within distribution centers.

Pharmaceuticals

Improve the accuracy and speed of pharmaceutical packaging processes, including bottles, cartons, and blister packs. This system ensures compliance with strict regulatory standards while minimizing manual handling risks.

Consumer Goods

Expedite the packaging of consumer goods like household products, personal care items, and electronics. The Conveyor & Robot Arm Palletizing system facilitates rapid palletization of diverse product formats, supporting efficient supply chain management.

Automotive

Streamline the handling and palletizing of automotive components, parts, and assemblies. This system enables automated stacking of items such as tires, engines, body panels, and more, enhancing overall production efficiency.

Chemicals & Petrochemicals

Enhance safety and efficiency in the handling of chemical products by automating palletizing tasks. This system ensures precise stacking of drums, barrels, and containers, reducing the risk of spills or accidents.

Retail & E-commerce

Meet the demands of omnichannel retail and e-commerce distribution with automated palletizing solutions. This system facilitates rapid pallet assembly for outbound shipments, supporting timely delivery and order fulfillment.