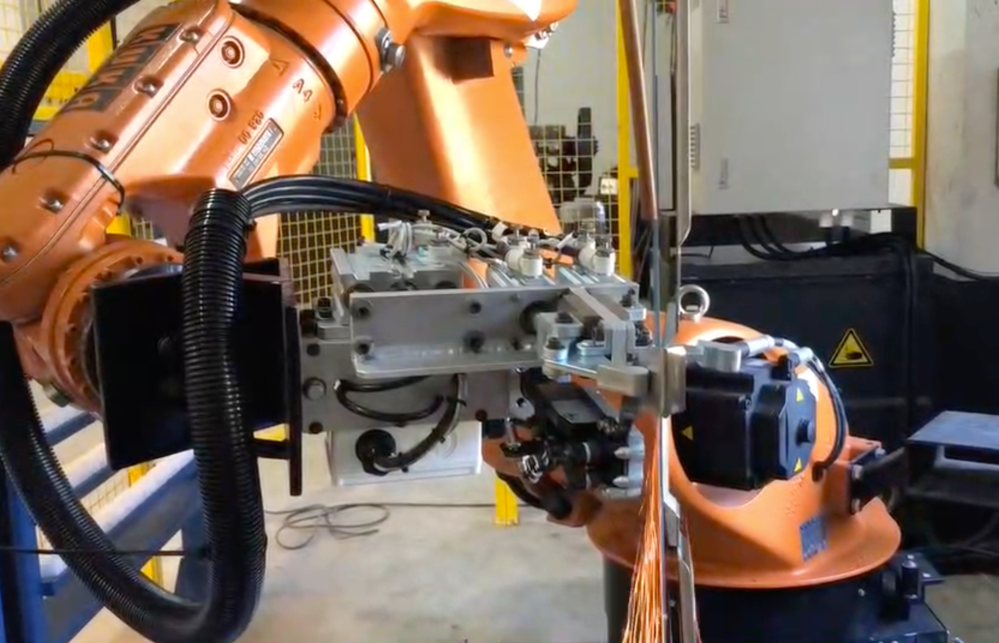

Robot Arm Grinding Project

Elevate your industrial grinding operations to new heights of precision and efficiency with our state-of-the-art Robot Arm Grinding Project. Engineered to redefine the standards of surface finishing and material removal, this innovative robotic system represents the pinnacle of advanced automation technology.

Crafted with meticulous attention to detail and backed by years of research and development, our Robot Arm Grinding Project seamlessly integrates cutting-edge hardware and intelligent software to deliver unparalleled performance across a myriad of industrial applications.

Precision Grinding

Experience unmatched precision and consistency in every grind. Our Robot Arm Grinding Project utilizes advanced sensors and proprietary algorithms to adapt to different surfaces and materials, ensuring uniformity and exceptional surface quality with every pass.

Versatility

From deburring and polishing to surface finishing and beyond, our robotic system is designed to excel in a multitude of tasks across various industries. Its versatility makes it the perfect solution for addressing the unique needs of diverse applications with ease and efficiency.

Efficiency Redefined

Revolutionize your production processes with unrivaled efficiency. Our Robot Arm Grinding Project streamlines operations, reducing cycle times and maximizing throughput. Experience significant cost savings and increased productivity as you optimize your workflow with our cutting-edge automation solution.

Safety First

Prioritize the safety of your workforce with our comprehensive safety features. Equipped with advanced collision detection systems, emergency stop mechanisms, and protective barriers, our robotic system ensures a secure working environment, minimizing the risk of accidents and injuries.

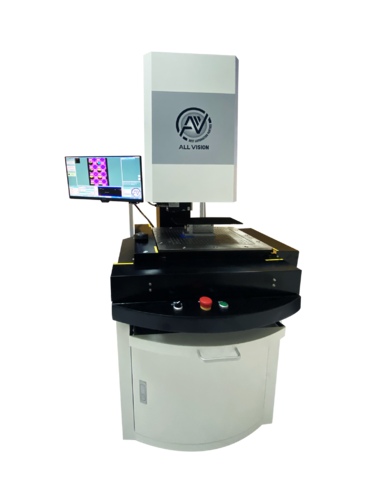

Intuitive Interface

Simplify operation and enhance user experience with our intuitive interface. Designed with user-friendly controls and customizable settings, operators can easily program and monitor the robotic system, optimizing performance according to specific requirements with minimal training.

Scalability & Integration

Whether you're a small-scale manufacturer or a large industrial facility, our Robot Arm Grinding Project offers scalability and seamless integration into existing production lines. Expand your capabilities effortlessly, adapting to changing demands without compromising on performance or efficiency.

Our Robot Arm Grinding Project is tailored to meet the demands of various industries, including:

Automotive

Optimize the production of automotive components with precision grinding solutions for weld seam blending, surface finishing, and edge deburring, ensuring superior quality and consistency in every part.

Aerospace

Maintain the highest standards of quality and performance in aerospace manufacturing with precision grinding capabilities for critical components such as turbine blades, engine casings, and structural elements.

Metalworking

Enhance efficiency and productivity in metalworking processes with our robotic system, ideal for grinding and polishing metal surfaces, removing imperfections, and achieving impeccable surface finishes in machined parts.

Medical Devices

Ensure precision and reliability in medical device manufacturing with our Robot Arm Grinding Project, perfect for intricate grinding operations on implants, surgical instruments, and other medical components, meeting stringent regulatory standards with ease.

Consumer Electronics

Enhance the aesthetics and functionality of consumer electronic products with flawless surface finishes achieved through our robotic grinding solution, perfect for smartphones, laptops, appliances, and more.