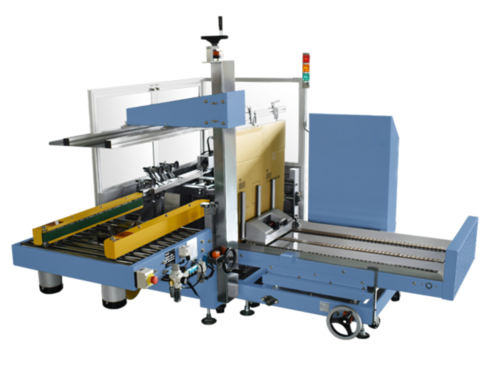

Horizontal Cartoning Machine

- The process begins with the carton erector, which forms flat carton blanks into three-dimensional boxes.

- These carton blanks are typically made from cardboard or similar materials.

2. **Product Loading:**

- Once the carton is formed, products are loaded into the carton. This can be done manually or automatically, depending on the specific machine design and application.

3. **Product Insertion:**

- Some vertical cartoning machines have mechanisms for inserting products into the cartons with precision. This could involve pushing, dropping, or otherwise placing the products into the carton.

4. **Leaflet or Instruction Manual Insertion:**

- In industries such as pharmaceuticals, there may be a step for inserting leaflets, instruction manuals, or other documentation into the cartons.

5. **Carton Closing:**

- The carton is then sealed using various methods, such as gluing, tucking, or folding, to ensure that the contents are securely enclosed.

6. **Coding and Marking:**

- Some machines may have the capability to code or mark the cartons with information such as batch numbers, expiration dates, or other product-related data.

7. **Carton Discharge:**

- Finally, the sealed and filled cartons are discharged from the machine, ready for distribution or further packaging processes.

1. **Speed:**

- CPM (cartons per minute):maximum 10-15 cartons.the speed can vary widely depending on the complexity of the cartoning process and the type of products being packaged.

2. **Carton Size Range:**

- Vertical cartoning machines are designed to handle a range of carton sizes.

3. **Product Size Range:**

- Under request

4. **Carton Material:**

- Cardboard or corrugated materials.

5. **Power Requirements:**

- 220V/380V/400V 3phase6. **Control System:**

- The control system include features like a touchscreen interface, programmable logic controller (PLC), and other automation technologies.

7. **Additional Features:**

- automatic changeover capabilities for quick adjustment between different carton and product sizes, code printing capabilities, and inspection systems.8. **Compliance and Safety Features:**

- Information on compliance with industry standards and safety features incorporated into the machine design.

- Vertical cartoning machines with a focus on customization allow for tailored solutions to meet specific packaging requirements. This may involve adapting the machine to handle unique carton sizes, product dimensions, or special packaging configurations.

2. **One-Stop Solution:**

- A comprehensive solution that integrates multiple packaging processes into a single machine. This includes carton erecting, product loading, sealing, and any additional features required for a complete packaging solution.

3. **High Flexibility:**

- The ability to adapt to different production needs and accommodate variations in carton sizes, product types, and packaging configurations. High flexibility ensures that the machine can handle a diverse range of products without the need for extensive reconfiguration.

4. **Quick Changeover:**

- Efficient changeover capabilities that allow for rapid adjustments between different carton sizes or product types. This feature enhances production efficiency and reduces downtime during transitions.

5. **User-Friendly Interface:**

- An intuitive and user-friendly control interface, possibly with a touchscreen panel or user-friendly software, to facilitate easy operation and adjustment of machine settings.

6. **Automation and Integration:**

- Advanced automation features that streamline the packaging process. Integration with other production line components and automation systems enhances overall efficiency and reduces the need for manual intervention.

7. **Versatility:**

- Versatile design that enables the machine to handle various packaging formats, including different carton styles (e.g., tuck flap, glue flap), product orientations, and packaging materials.

8. **High Production Speed:**

- Capable of high-speed packaging to meet the demands of fast-paced production environments. The machine's speed contributes to increased overall production efficiency.

9. **Quality Control Systems:**

- Integrated quality control mechanisms such as sensors, cameras, or inspection systems to ensure accurate and consistent packaging quality. This helps in identifying and addressing potential issues during the packaging process.

10. **Modular Construction:**

- A modular design that allows for easy expansion or modification of the machine to accommodate future changes in production requirements. This modularity contributes to long-term adaptability and scalability.

11. **Compliance with Industry Standards:**

- Adherence to industry regulations and standards to ensure that the packaging process meets necessary quality and safety requirements.

12. **Remote Monitoring and Diagnostics:**

- Connectivity features that enable remote monitoring of the machine's performance and diagnostics. This facilitates proactive maintenance and troubleshooting, reducing downtime.

- Vertical cartoners are used for packaging food items such as cereal boxes, snacks, frozen foods, and beverages. They handle a range of carton sizes and configurations to accommodate different product dimensions.

2. **Pharmaceutical Industry:**

- Vertical cartoning machines are utilized for packaging pharmaceutical products, including tablets, capsules, vials, and syringes. They often include features for inserting informational leaflets and ensuring the precise placement of products within cartons.

3. **Cosmetics and Personal Care Products:**

- Beauty and personal care items, such as skincare products, cosmetics, and toiletries, are often packaged using vertical cartoning machines. These machines provide flexibility in handling various packaging formats and product shapes.

4. **Healthcare Products:**

- Products in the healthcare sector, such as medical devices, diagnostics kits, and first aid supplies, can be efficiently packaged using vertical cartoners. The machines can ensure accurate and secure packaging of these sensitive items.

5. **Home and Cleaning Products:**

- Vertical cartoning machines are used in the packaging of household and cleaning products, such as detergent boxes, soap bars, and cleaning supplies. Their flexibility allows for different carton sizes and packaging configurations.

6. **Electronics and Technology:**

- Vertical cartoning machines play a role in packaging electronic devices and accessories, including cables, adapters, and small gadgets. They can handle varying product sizes and shapes with precision.

7. **Automotive Aftermarket:**

- In the automotive industry, vertical cartoners are employed for packaging spare parts, tools, and automotive accessories. Their adaptability allows for the efficient packaging of items with diverse shapes and sizes.

8. **Hardware and Tools:**

- Tools, hardware items, and DIY products are often packaged using vertical cartoning machines. These machines can handle packaging for items like drills, screws, and small hardware components.

9. **Textile and Apparel:**

- Vertical cartoning machines are used for packaging textiles and apparel items such as shirts, socks, and undergarments. They provide a reliable and efficient solution for folding and packaging clothing items.

10. **E-commerce Fulfillment Centers:**

- With the rise of e-commerce, vertical cartoning machines are increasingly used in fulfillment centers for packing a variety of products before shipping. Their adaptability allows for handling a wide range of products sold online.

Horizontal cartoning machines offer a versatile packaging solution, and their applications can extend to any industry that requires the efficient and automated packaging of products into cartons. Their ability to handle different carton sizes, product configurations, and packaging materials makes them suitable for diverse production environments.